Bridge Engineering

Application cases of rotary dehumidifiers in bridge projects:

|  |  |  |

Prevent structural corrosion Protect Steel Structure: The main materials of bridges such as steel and concrete are prone to corrosion and deterioration in humid environments. The rotary dehumidifier can effectively reduce the humidity inside the bridge and reduce the damage of moisture to the materials, thereby extending the service life of the bridge. For example, when the relative humidity in the air exceeds 60%, the corrosion rate of steel increases exponentially, while when the relative humidity is below 50%, the corrosion rate is extremely low.

Reduced Maintenance Costs: By using a rotary dehumidifier, bridge maintenance and repair costs can be reduced. Prevents moisture-induced damage, reducing the need for frequent bridge repairs and reinforcements.

Improve security Ensure structural stability: Excessive humidity may cause safety hazards to the bridge structure, such as corrosion of steel bars, cracking of concrete, etc. By using a rotary dehumidifier, the stability of the bridge structure can be maintained and traffic safety ensured.

Extended service life: By effectively controlling humidity, rotary dehumidifiers can significantly extend the service life of bridges and reduce structural problems caused by humidity, thereby increasing the overall return on investment.

Improve environmental conditions Reduce mold growth: Dehumidifiers can improve the environmental conditions around the bridge, reduce the humidity in the air, reduce the growth of mold and other harmful substances, and help protect the bridge and its surrounding facilities.

Adapting to Climate Change: As the frequency of extreme weather due to climate change increases, so do the moisture challenges faced by bridges. Rotary dehumidifiers can help bridges adapt to these changes and maintain their functionality and safety.

Technical advantages Efficient dehumidification: The rotary dehumidifier adopts advanced patented solid adsorption technology, which can continuously and stably operate large-load air humidity control, especially under low temperature and low humidity conditions, it can achieve an ultra-low air dew point of -70°C.

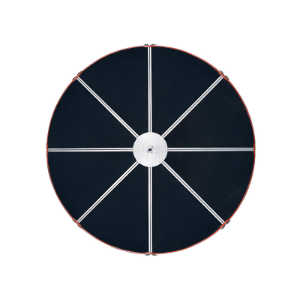

Stable operation: After the dehumidification wheel of the rotary dehumidifier absorbs water molecules in the air treatment area and reaches a saturated state, it enters the regeneration area and is desorbed and regenerated by high-temperature air. This process repeats itself, and the dry air is continuously temperature-regulated. Then it is sent to the designated space to achieve high-precision temperature and humidity control.

Intelligent control: The control system adopts PLC control and has a good operating interface. It can digitally display various important temperatures and highlight the operating status of each major component. When a fault occurs, it can automatically diagnose and indicate the type of fault.

Practical applications Application: Since the adoption of new technologies in Europe in the 1970s, the possibility of corrosion of steel beams, steel cables, etc. has been basically eliminated, thereby ensuring the normal service life and maintenance of the bridge. The maintenance cost is only 10- 20%. Rapid dehumidification: The bridge-specific dehumidifier can quickly dehumidify. When the bridge manhole door is closed, it can reach an extremely dry environment within 2 hours. The equipment can continue to maintain a dry environment within the bridge body.