Rubber Industry

Used in the storage and processing of rubber to prevent rubber from aging and deformation.

Humidity/Process Requirements

Target Humidity Range: 40~60% RH

Challenges

Humidity control is vital in the rubber industry to ensure product quality, efficient processing, and the durability of both raw materials and finished goods:

Material Degradation: Excessive moisture can cause rubber compounds to absorb water, leading to reduced elasticity and performance.

Defects During Curing: High humidity disrupts the curing process, resulting in uneven hardness, shrinkage, and surface imperfections in finished rubber products.

Corrosion of Machinery: Humid conditions accelerate corrosion of molding machines, extruders, and other processing equipment, increasing maintenance costs.

Mold and Mildew Growth: Raw rubber stored in high-humidity environments is prone to microbial growth, which can degrade materials.

Solutions

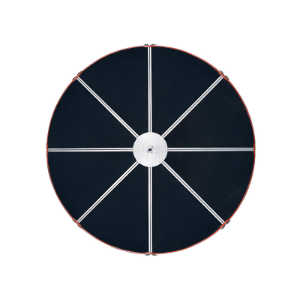

Rotary dehumidifiers provide precise humidity control to address these challenges effectively:

1. Improved Material Quality:

Maintains low-humidity levels to prevent water absorption in rubber compounds, preserving elasticity and performance.

2. Defect-Free Curing:

Ensures consistent curing conditions, reducing shrinkage, bubbles, and other defects in finished products.

3. Machinery Protection:

Reduces moisture-related corrosion in machinery, extending equipment lifespan and minimizing downtime.

4. Preservation of Raw Materials:

Controls storage conditions to prevent mold and mildew growth, ensuring the quality of raw rubber materials.

5. Enhanced Production Efficiency:

Stable humidity control ensures smooth processing and reduces waste caused by defective products.

Rotary dehumidifiers are a critical solution for maintaining product quality, operational efficiency, and material longevity in the rubber industry.