- Highly Efficient And Energy-Saving Rotor Dehumidifieru

- Nique Internal Frame Structure With Integrated Foaming Design Toprevent Cold Bridging.

- Plc Control System For Easy Operation And Real-Time Monitoring Ofoperating Conditions.

- Larger Maintenance Space Design For Quick And Convenient Servicing.

- Imported High-Efficiency Rotor With Antibacterial And Flame-Retardant Properties.

- Adjustable Air Valves For Both Process And Regeneration Airflow.

- Adjustable Front And Rear Water Valves For Optimal Performance.

- Two Heating Options Available: Electric Heating Or Steam Heating.

- Bottom Channel Steel Design For Easy Handling And Transportation.

Product Description

Steam regeneration conventional unit

| Model | Air volume(m* /h) | A | B | H | H1 | C | H2 | H3 | D | H4 | H5 |

| YH-AHD40D | 4000 | 2000 | 1550 | 1550 | ≤700 | 1000 | 250 | 500 | 1000 | 250 | 500 |

| YH-AHD5OD | 5000 | ||||||||||

| YH-AHD6OD | 6000 | ||||||||||

| YH-AHD8OD | 8000 | 2000 | 1900 | 2000 | ≤950 | 1200 | 400 | 1000 | 1200 | 400 | 1000 |

| YH-AHD120D | 12000 | ||||||||||

| YH-AHD150D | 15000 | 2500 | 2300 | 2240 | ≤1200 | 1600 | 400 | 1200 | 1600 | 400 | 1200 |

| YH-AHD180D | 18000 | ||||||||||

| YH-AHD200D | 20000 |

Electric regeneration conventional unit

| Model | Air Volume (m³/h) | A | B | H | H1 | C | H2 | H3 | D | H4 | H5 |

| YH-AHD10D | 1000 | 2000 | 1350 | 1350 | ≤700 | 800 | 250 | 500 | 800 | 250 | 500 |

| YH-AHD15D | 1500 | ||||||||||

| YH-AHD30D | 3000 | ||||||||||

| YH-AHD40D | 4000 | 2000 | 1550 | 1550 | ≤700 | 1000 | 250 | 500 | 1000 | 250 | 500 |

| YH-AHD50D | 5000 | ||||||||||

| YH-AHD60D | 6000 | ||||||||||

| YH-AHD80D | 8000 | 2000 | 1900 | 2000 | ≤850 | 1200 | 400 | 1000 | 1200 | 400 | 1000 |

| YH-AHD120D | 12000 | ||||||||||

| YH-AHD150D | 15000 | 2500 | 2300 | 2240 | ≤850 | 1600 | 400 | 1200 | 1600 | 400 | 1200 |

| YH-AHD180D | 18000 | ||||||||||

| YH-AHD200D | 20000 |

Note: The dimensions are for reference only. Please refer to the actual delivered unit. If there are any design changes,we will not notify you separately.

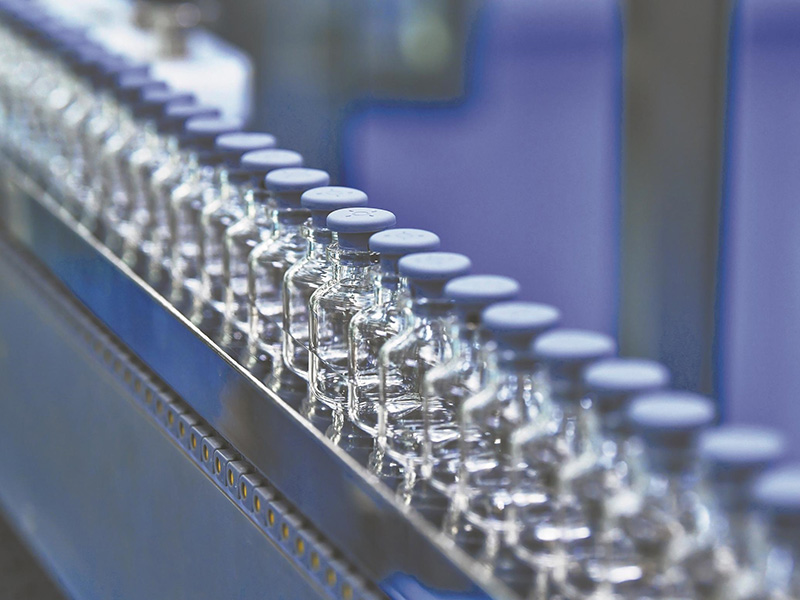

1.Food and pharmaceutical related industries

(1) Humidity/Process Requirements Target Humidity Range: 40~50% RH (2) Challenges Large temperature and humidity fluctuations Slow humidity control response (3) Solutions Optimal model selection and solution Precise temperature and humidity control Rapid response to provide a stable process environment |  |  |  | ||

|  |  |

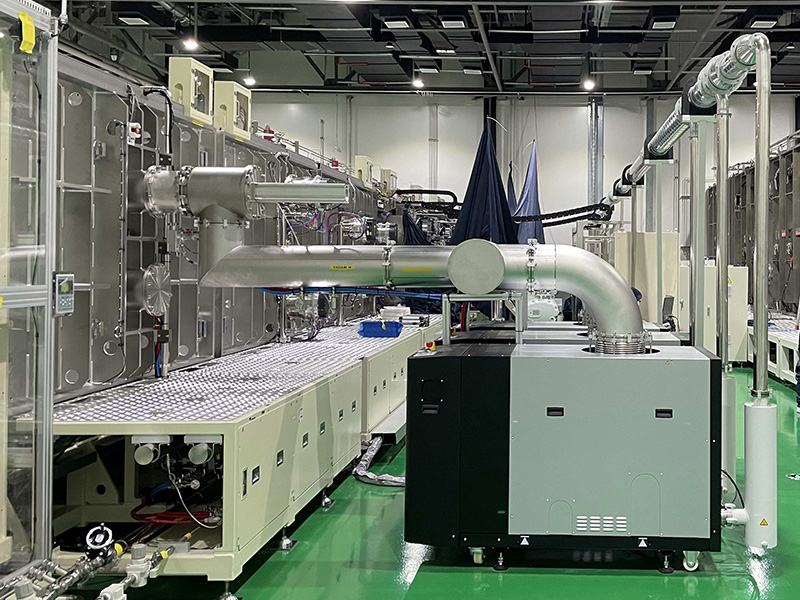

2.Precision Casting (Photovoltaic Cells) Related Industries

(1) Humidity/Process Requirements Target Humidity Range: 10~40% RH (2) Challenges Severe energy waste with conventional rotor dehumidification. Difficulty in achieving the low humidity required for the process. High regeneration exhaust temperature, leading to shorter rotor lifespan. (3) Solutions Unique rotor materials + optimized solutions to improve rotor lifespan. Stable low-humidity air supply. Eliminate energy waste |  |  |  | ||

|  |  |